-

Introduction to DTF Transfers

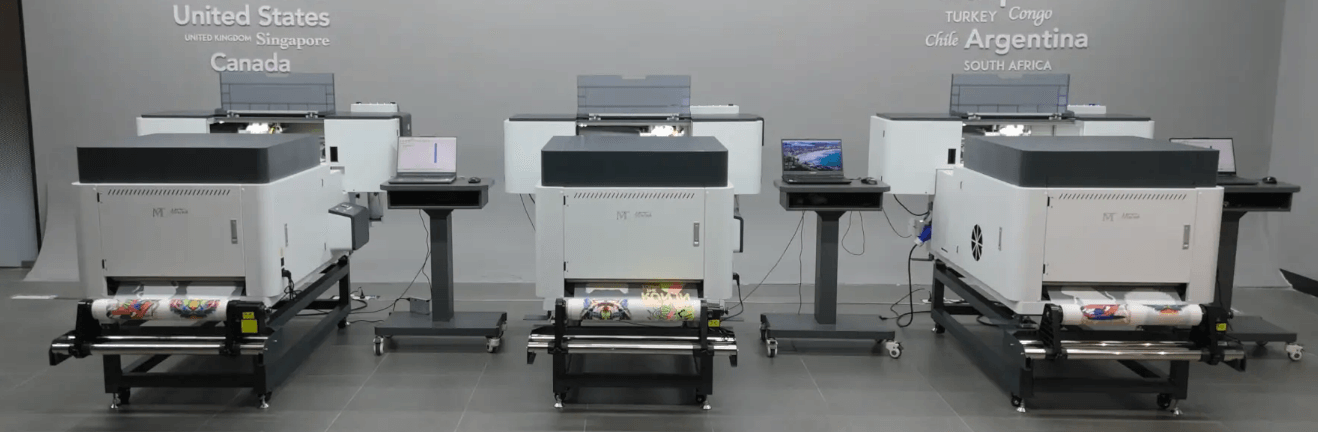

Direct to Film (DTF) transfers have revolutionized textile printing. This innovative technique involves printing a design onto a specialized PET film, applying a powder adhesive, and then heat-pressing the film onto fabric. The result? A vibrant, high-quality print that’s easy to apply to a wide range of materials.

Why Choose DTF Over DTG and Vinyl?

Though Direct to Garment (DTG) and vinyl are popular for textile printing, DTF transfers stand out with unique benefits:

- Versatility in Fabric Choice: DTF transfers work on nearly any fabric, including cotton, polyester, silk, and blends. DTG, by contrast, typically works best on cotton.

- Color Vibrancy and Detail: DTF produces exceptionally vibrant and detailed prints, even on darker fabrics, offering more consistent color quality than DTG.

- Durability and Soft Feel: Known for their wash-resistant durability, DTF transfers don’t fade or crack after multiple washes. They also feel softer than the thicker, sometimes plastic-like texture of vinyl.

- Cost-Effectiveness and Efficiency: Without the pre-treatment needed for DTG, DTF saves time and costs, making it ideal for custom and small-batch printing.

- Eco-Friendliness: DTF printing uses less water and creates less waste than DTG, making it a more environmentally friendly choice.

The Future of Textile Printing

With its high-quality results, durability, cost-efficiency, and eco-friendly advantages, DTF transfers are reshaping the textile printing landscape. As the technology advances, DTF is poised to become an industry favorite, bringing long-lasting, vibrant prints to creators and businesses alike.